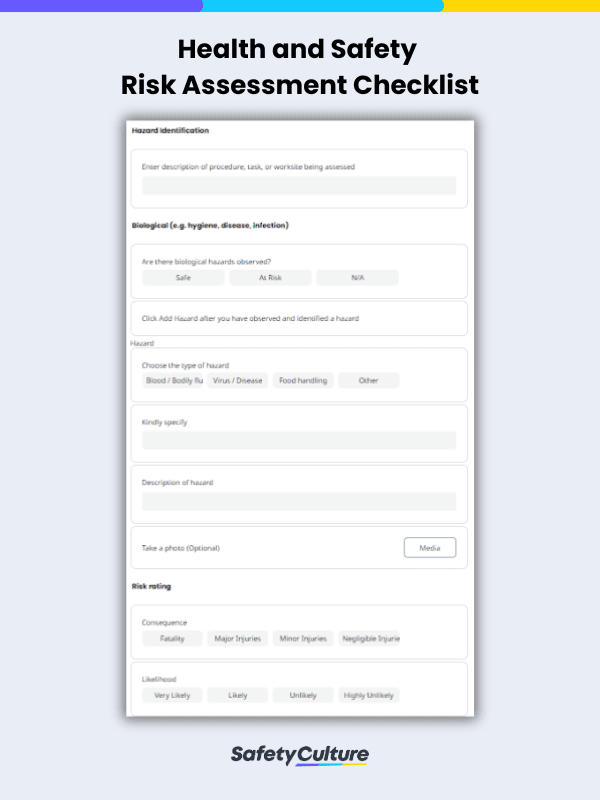

Health and Safety Risk Assessment Checklist

This general health and safety risk assessment checklist allows you to do the following:

- Add basic information about the risk assessment, such as date and time of inspection, location, name of the inspector, and client or company name

- Enter the description of the procedure, task, or worksite being assessed

- Determine if there are biological and chemical hazards, critical incidents, and energy systems, environment, facilities, machinery, and ergonomics issues observed

- Specify the type of hazards of issues

- Define the level of risk rating via consequence and likelihood

- Choose appropriate control measures to counter the hazard (elimination, substitution, engineering controls, administrative controls, PPE, others)

- Monitor and review the effectiveness of chosen controls

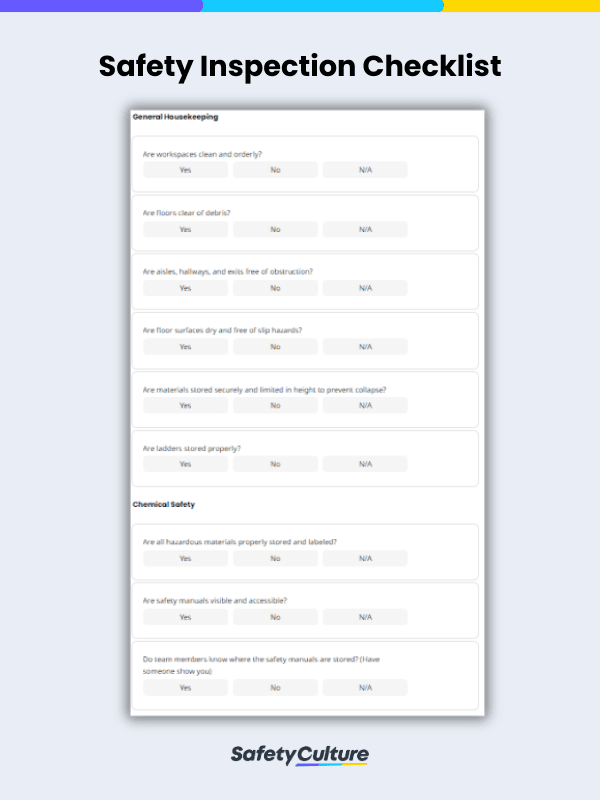

Safety Inspection Checklist

Safety inspections differ based on the environment and industry of a business, but some of the aspects and questions to ask are the following:

General Housekeeping Safety

- Are workspaces clean and orderly?

- Are aisles, hallways, and exits free of obstruction?

- Are materials stored securely and limited in height to prevent collapse?

Chemical Safety

- Are all hazardous materials properly stored and labeled?

- Are safety manuals visible and accessible?

- Do team members know where the safety manuals are stored? (Have someone show you)

Emergency Systems

- Are emergency exit maps posted and clearly marked?

- Are emergency exits free from obstructions?

- Are fire extinguishers current on inspection?

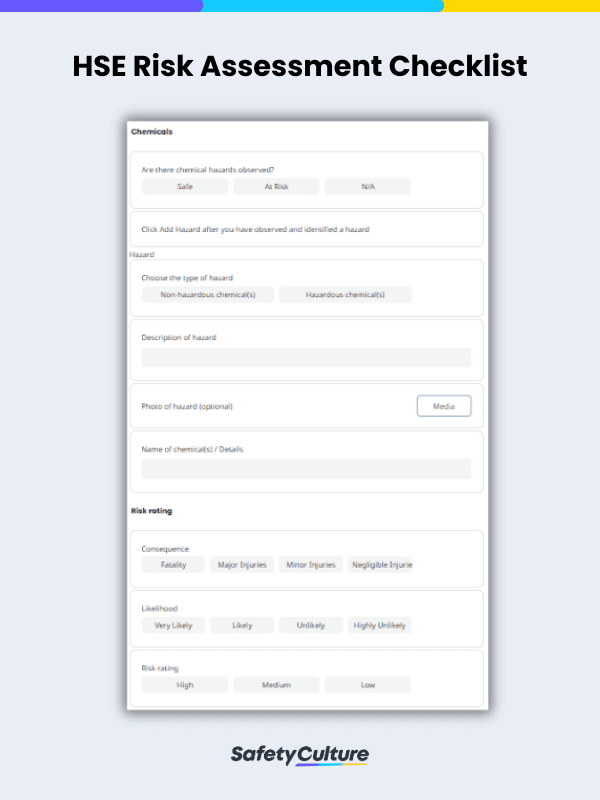

HSE Inspection Checklist

HSE (Health, Safety, and Environment) focuses on ensuring the health, safety, and well-being of individuals in a facility and workplace, while also considering the potential impact a business may have on the environment.

Here are the key steps for performing a reliable HSE risk assessment:

- Identify hazards – List all potential hazards associated with the workplace, processes, or activities. This may include physical, chemical, biological, ergonomic, and psychosocial hazards.

- Assess risk severity – Consider all the listed risks and define their severity by associating the potential consequence those risks may have. This can include injuries, minor, and major injuries, as well as fatality.

- Evaluate risk likelihood – Determine the probability of the risks happening by tagging them as very likely, likely, unlikely, and highly likely.

- Analyze the risk – Combine the severity and likelihood assessments to determine the overall risk level associated with each hazard. This can be done by using a risk matrix or other methods that assign risk levels based on the intersection of severity and likelihood.

- Select control measures – Choose preventive or control measures to minimize or eliminate the identified risks. This includes elimination, substitution, engineering controls, administrative controls, PPE, and others.

- Implement control measures – Put the identified control measures into action and ensure that the necessary resources, training, and communication are provided to effectively enforce them.

- Monitor progress – Ensure the effectiveness of measures by performing periodic reassessments of hazards and risks, while considering any changes in processes, equipment, or regulations.

Use this customizable template to efficiently and effectively conduct HSE risk assessments in your organization.

EHS Audit Checklist

Use this Environment Health and Safety Audit to conduct a visual inspection of the workplace by doing the following activities:

- Check the general safety of the site

- Identify electrical and fire hazards and capture photos as evidence

- Evaluate if proper laboratory controls are applied to prevent contamination and overexposure to chemicals

- Assess the condition of vehicles used for the operation to prevent vehicular accidents, if applicable.

- Add recommendations and a digital signature to complete the inspection report.

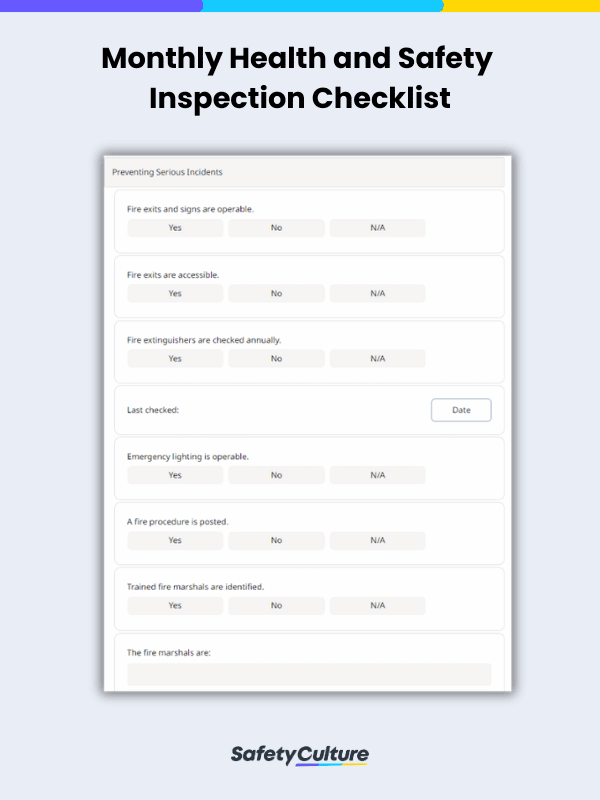

Monthly Health and Safety Inspection Checklist

This monthly health and safety inspection checklist specifically focuses on restaurants and can be used by businesses in the hospitality industry to do the following:

- Ensure proper communication and setting of expectations

- Prevent serious incidents involving emergencies and electrical issues

- Prevent strains and sprains

- Prevent cuts and lacerations

- Prevent chemical poisoning and other related hazards

- Prevent burn injuries

- Confirm implementation of incident investigations

- Review records and statistics

- Assess first-aid approach

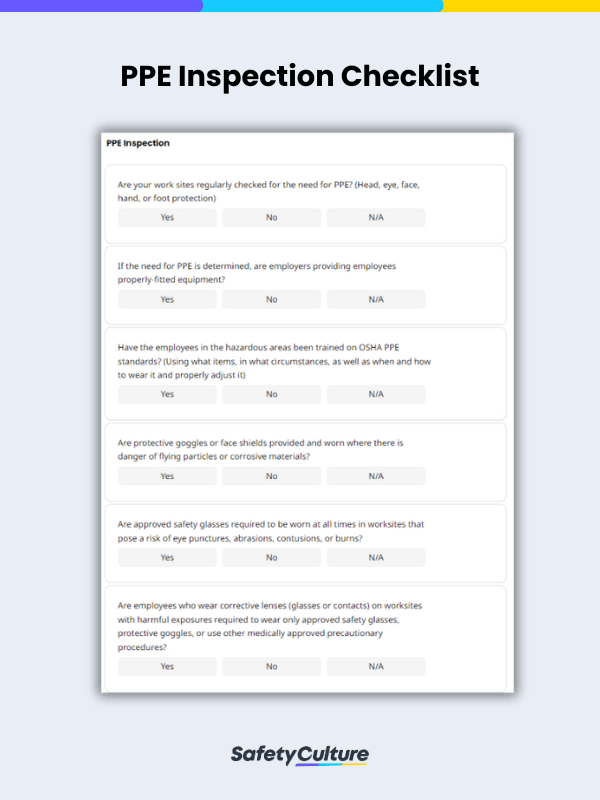

PPE Inspection Checklist

The purpose of PPE inspection is to ensure that the equipment is in proper working order, free from damage or defects, and capable of providing the necessary protection. The things to do during the inspection are:

- Visual examination

- Functionality assessment

- Cleanliness check

- Component inspection

- Compliance evaluation

- Documentation

This OSHA PPE Checklist contains 17 general inspection items to determine the need for PPE in protecting the workers, as well as equipment checks and evaluation of compliance with safety rules when utilizing the equipment.