What are Hazard Control Measures?

To minimize risks and prevent incidents, the National Institute for Occupational Safety and Health (NIOSH) developed the hierarchy of controls. Its purpose is to guide workplaces in implementing the most feasible and effective control solutions.

There are 5 types of controls that can be applied, each intended for a specific purpose:

1. Elimination

This control is considered as the most effective method. It involves physically removing or eliminating the hazard from the environment where it poses risks to people (e.g., hazardous equipment, machines, tools, assets, or materials).

2. Substitution

This control acts as the second defense. It replaces the hazard with something that’s less or non-hazardous. For example, replacing a cleaning chemical with something that doesn’t produce harmful fumes.

3. Engineering Controls

When a hazard can’t be controlled through means of the first two controls, the next best option is to apply engineering controls. This means, rearranging the work environment to isolate people from the hazard. For example, placing guardrails or fences around areas with high voltage equipment, use of sound dampening materials, and other more.

4. Administrative Controls

Less effective than the ones above, but nonetheless keeps people safe by directing people to safer work procedures. Using rules and policies, warning signs and labels, and training.

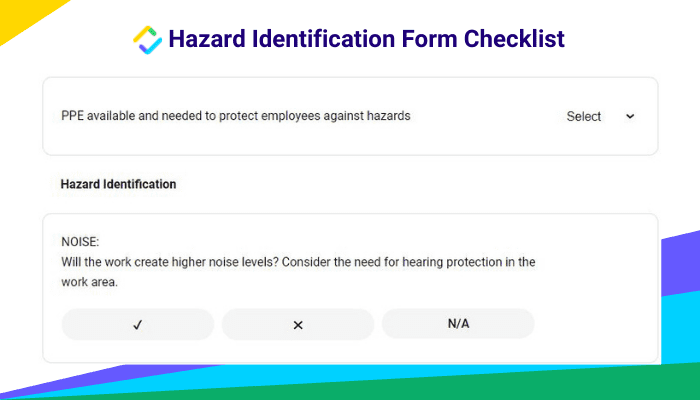

5. PPE

As the last line of defense, PPE’s are designed to equip people with the right equipment to combat hazards. Common PPE includes helmets or hard hats, goggles, gloves, boots, respirators, and high visibility clothing.

In choosing the most effective control, employers will have to rely on the data gathered from a safety audit and the information provided by workers.